Specially formulated, semi-rigid low density polyurethane foam which is manufactured at our Swedish plant, Autins’ light foam provides excellent acoustics for a low density whilst maintaining a low flame response. This product is particularly suited to thermoforming and can be used in exterior and engine bay compartments in the automotive industry.

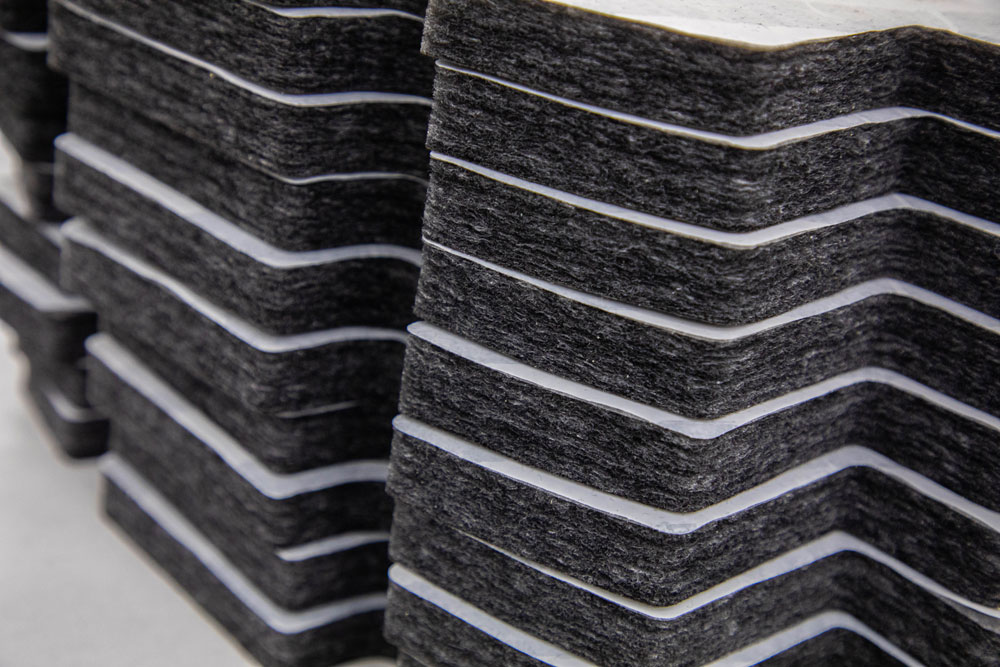

Large blocks of the light foam product are created in a reactive process and these can be supplied either in block form or sliced into sheets at a range of different thicknesses. This product has a low density at just 15kg/m3 but provides excellent acoustic properties; this can be particularly advantageous in areas where weight is of importance.

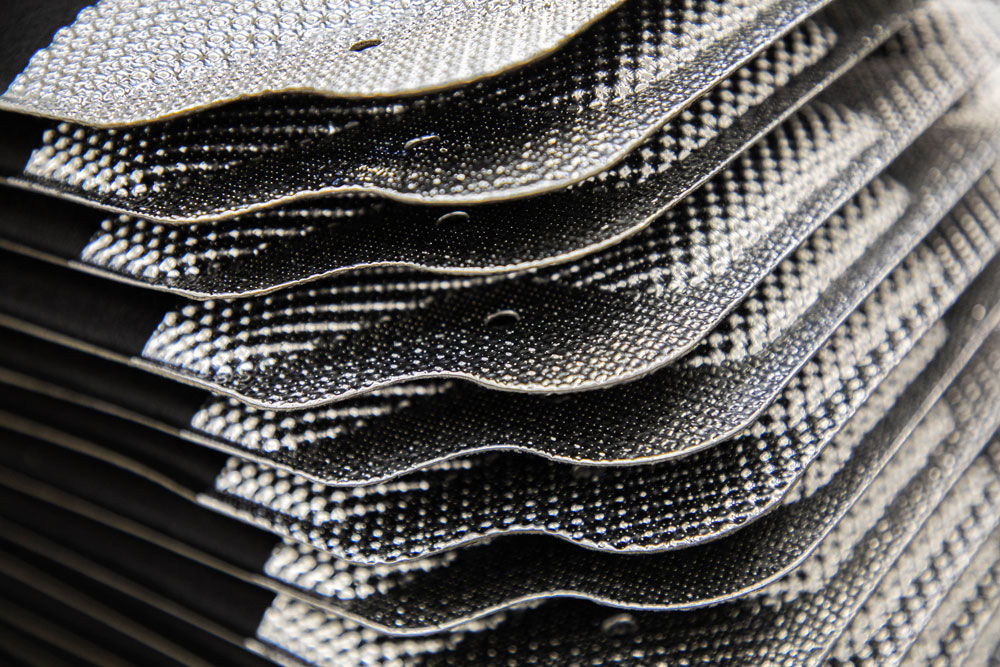

For automotive applications, the foam is typically covered on both sides with black oleophobic and hydrophobic cover fleeces and then formed into bespoke components. The addition of water and oil repellent covers ensures that light foam parts are suitable in a range of vehicle environments including the exterior and the engine bay.

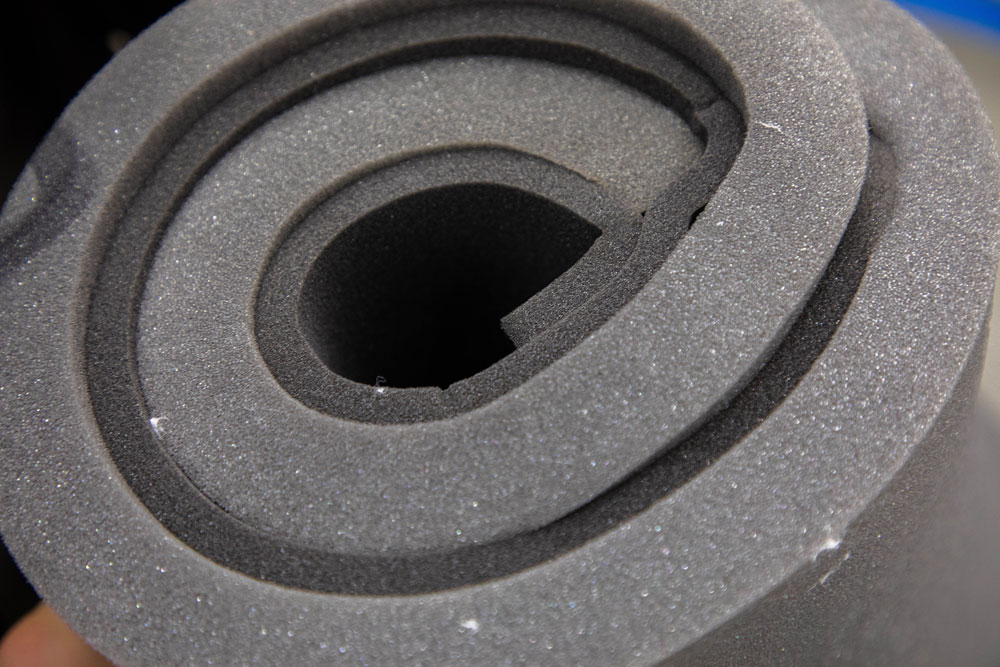

Component manufacture is realised via a thermal moulding process which allows the foam to be manipulated to exact customer specifications. This can include incorporating variable thicknesses across the surface area or adding metallic heat shields in localised areas.